Ray M. Owen

Before the days of the automatic gearbox, the petrol-electric transmission enjoyed a certain vogue, particularly as it was invented in the era of the non-synchromesh or 'crash' gearbox. However although the petrol-electric was easy to use, it was also expensive to build, bulky and heavy, which made it more suitable for commercial vehicles (such as the Tilling- Stevens) than for the private car.

There were one or two notable exceptions to this general rule, however, and one of the more ingenious electric transmissions was conceived just before World War 1 by Ray M. Owen of the Baker, Rauch & Lang company of Cleveland, Ohio, who were renowned for their Baker and Raulang battery electric cars.

The Entz Transmission

Owen adapted the Entz transmission, which was designed for use in the new generation of oil-engined battleships (such as the 1919 New Mexico), for automotive use, and began production of a luxury car with this form of drive in 1914. Under its original name of Owen Magnetic, the 'Car of a Thousand Speeds' was not very successful, but by 1920 J. L. Crown had taken over the design rights, and was producing cars in a factory at Wilkes-Barre, Pennsylvania.

Crown, it appears, was more interested in the European market than the American, and in the autumn of 1920 he arrived in England with a 38 hp Owen Magnetic touring car, and he then set about selling the manufacturing rights. W. Harold Johnson of Conquest magazine took the Owen-Magnetic, which was fitted with a 6864cc ohv six-cylinder engine, for a trial run.

He wrote, 'Except for its transmission system (a very big exception) the car is a conventional member of the highest class of petrol propelled vehicles. The engine is large - 38 hp - and the car itself is big. On the road it has all the characteristics that one expects to find in a car which is both luxurious and expensive. Instead of the ordinary clutch, the flywheel carries, on an extension of its flange, a set of electro-magnets. On the end of the propeller shaft and between these magnets is mounted an armature, and just behind this armature is situated a second.

Obviously, if either of these armatures be compelled to revolve the propeller shaft revolves with them, or, conversely, whenever the car is moving along the road these two armatures are also revolving. Around the first armature, the field magnets on the flywheel revolve whenever the engine is turning. Around the second armature is placed a second set of field magnets, which are bolted rigidly to a casing, and cannot revolve under any circumstances.

Assume that the engine is started and that the car is stationary, the magnets of the first of the two electrical units mentioned are now revolving round their armature, which is, of course, stationary. The result is the generation of current, the unit forming an ordinary electric dynamo. But, besides generating current, the two units of the primary motor, or dynamo, are exercising a mutual drag, and there is a tendency for the rotating magnets to pull the armature round with them. Now suppose it is desired to start the car.

The controlling switch is put in such a position that the current generated by what may be termed the slipping between rotating magnets and the armature is directed to the secondary motor. As soon as the magnets of this unit are energised, the armature is made to revolve, so that there are two forces at work, both tending to turn the propeller shaft and so propel the car. The first is the magnetic drag between the two units of the first motor. The second is the ordinary electric motor action in the secondary motor. The practical effect of putting the switch into the number one position of the quadrant on the steering wheel is that the car will almost imperceptibly move forward.'

The speed control quadrant was calibrated to show a 'charging' position, in which the engine could be run while the car was at a standstill to top up the 24 volt starting and lighting batteries; a 'starting' position, in which current from these batteries was used to spin the engine via the primary motor; 'neutral' and six speeds forward, in which the current supplied -to the secondary motor was progressively reduced, until, in 'high', the rotating magnets and their armature were magnetically locked together and no current was passing to the secondary unit. In fact, as there was no mechanical connection between magnets and armature, there was a perceptible amount of slip between them.

Oddly enough, tests showed that whether the engine was turning at 1000 or 3000 rpm, there was always a difference of 80 rpm between flywheel speed and armature speed. Or, as W. Harold Johnson put it: 'When the car is on the road, there is a delightful absence of that sense of friction that is always more or less present in the transmission system of an ordinary car'. Another advantage was that the car could coast once it had gathered sufficient momentum, or was running downhill, with consequent fuel economies. If the car was put into 'neutral' while coasting, the motors were converted into a powerful electromagnetic brake, which became ineffective below 15mph, so that it could never cause the wheels to lock and skid.

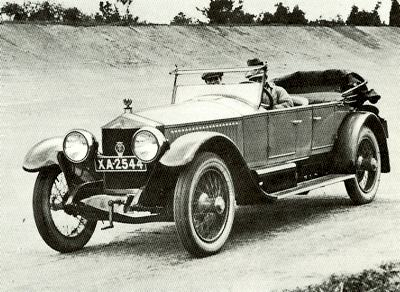

Owen Magnetic in British Crown Magnetic form. It was powered by a 6864cc 38 hp engine.

Owen Magnetic in British Crown Magnetic form. It was powered by a 6864cc 38 hp engine.

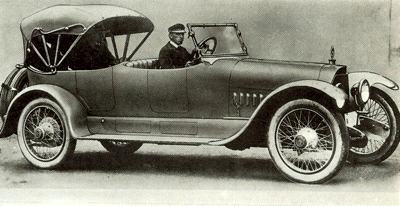

Owen Magnetic Limousine.

Owen Magnetic Limousine. |

The braking effect also came into action when the car was starting on a hill, so that it could not run backwards. A separate gearbox gave a reverse gear (in which all speeds were theoretically available) and an emergency low. But when Crown began production (and changed the car's name to Crown Magnetic) the emergency low was omitted, which proved to be a big mistake, as even with aluminum tourer bodywork and wings the car scaled over two-and-a-half tons in going order, which meant that on a long steep hill, the force of gravity could defeat the 'magnetic drag' and bring the car to an ignominious stand-still - as happened when the Crown Magnetic was being demonstrated to some Welsh businessmen who, it was hoped, might finance its production in Britain.

W. Harold Johnson demonstrated this drawback in a more amusing fashion: 'The switch on the steering wheel was put in the 'number one' position (there being no occupant of the driving seat) and, as the car moved forward, I walked to the front of it, placed my hand and my weight against the radiator, and held the car stationary. Then I moved away and, as I did so, the car gradually moved forward again.' J. L. Crown then fitted the Owen Magnetic transmission to a number of

Minerva cars; these transmissions were built to his order by Greenwood & Barley of Leeds, better-known as makers of electric milk floats.

The company reorganized as the Owen Magnetic Motor Car Corporation based in Wilkes-Barre. The newly-equipped factory was situated in the old Matheson works at Forty Fort, Pennsylvania. The Wilkes-Barre Times announced the resumption of production for January 1, 1920, with the aim of producing 750 cars that year. The company received an order for 500 vehicles from Crown Limited of Great Britain. Under the terms of the agreement, the cars were named Crown Magnetic. However by August 1920, before the order could be fulfilled, Owen Magnetic was in receivership.

British Ensign

Crown then decided to join forces with the British Ensign company of Willesden, run by Edward Gillett: in July 1923 he and the company's chief engineer, T. E. B. James took an American-built Owen Magnetic on a sales tour across Europe. The handsome vee-radiator boiled crossing the Mont Cenis Pass, and the car was involved in a traffic incident in Modane; neither Fiat nor Isotta-Fraschini were interested in taking up the engineering rights, and all in all the trip was an expensive waste of time. British Ensign had already built one Ensign Magnetic, using their existing luxury chassis, which had an ohv 6105cc engine developing over 100 bhp. Now they began work on a second, which was intended for one of their directors, a Welshman named Rees, who was also manager of the Glanmore Foundry of Llanelly.

Rees had lost a leg in an accident at the foundry, and reckoned that the Ensign Magnetic, with its steering-wheel controls and only two pedals, was just the car for him. But as work started, J. L. Crown decided that there was no future in magnetic transmissions: he withdrew his capital from British Ensign and took it over to Germany, where he made a fortune dealing in the fallen Mark, and used it to buy up a number of properties, including a large hotel. T. E. B. James finished Rees's car amid an atmosphere of gloom: British Ensign were virtually broke, and had dismissed most of their staff.

One or two Owen Magnetics, including one belonging to General Ironside, came in for repair, and there was a desultory attempt at building a sub-utility £100 car, the Gillett, but there was obviously no future for the company, even as a magnetic transmission repair specialists, and they closed down. In any case, there was little market for a car of this complexity at a chassis price of virtually £2000; although the transmission was generally reliable, except for a tendency to burn out the ball-bearing at the front end of the propeller shaft, customers were wary of having to employ a qualified electrical engineer as chauffeur.

By this time the American end of the operation was dead - Crown had closed down the Wilkes-Barre works soon after he came to Europe - and with the bankruptcy of the Willesden company.