|

Frazer Nash

|

1922

- 1960 |

Country: |

|

|

Fewer than 500

'The Frazer Nash possesses an all-round performance unequalled by any other sports car, the docility of a touring car combined with fierce acceleration, capacity for speed, and that "glued-to-the-road" feeling of the thoroughbred racer.' In such glowing terms did Frazer Nash Cars describe their products in their 1936 catalogue; and, unusually, the hyperbole of a catalogue description could be equated with the truth.

The place of the Frazer Nash in motoring history is assured, a fact which becomes all the more remarkable when you consider that fewer than 500 Frazer Nash cars were produced during the marque's 36 year currency, of which something in the region of 300 were the famous chain-driven models on which the company's reputation was founded.

The GN Cyclecar

It is impossible to consider the Frazer Nash car without mentioning its direct ancestor, the GN cyclecar. The story of that venture began in 1905, with a chance meeting between two young engineering students, Ronald Godfrey and Archibald Goodman Frazer-Nash, who had just signed on for a City & Guilds mechanical engineering course at Finsbury. They discovered a mutual interest in motor vehicles, and Godfrey sold Nash a 11 hp Clement motor-cycle engine which was eventually incorporated into the first Frazer Nash 'creepabout' four-wheeler, built in the stables of his mother's house at Hendon.

Willans and Robinson

Soon afterwards, Godfrey & Frazer-Nash became apprentices with Willans and Robinson, the Rugby engineering company which had built the British Duryea. During this period, both men made light motor vehicles in their spare time and, after Frazer-Nash had left Willans & Robinson in 1909, he built a sporting cyclecar which attracted the attention of the Editor of The Motor Cycle; the resulting publicity attracted three firm orders, and Frazer-Nash decided to ask Godfrey to join him in the manufacture of cars to this basic design. Their resources were decidedly sketchy: two treadle lathes, a drilling machine and various hand tools.

The car's design was correspondingly basic, with a wooden chassis carrying a V-twin JAP engine and a primitive two-speed transmission, in which the two ratios were given by sliding dog clutches which keyed chain-and-sprocket gearing to one or other of the rear wheels. As the final-drive sprockets were of different diameters, one wheel was driven for low gear, the other for high. Steering was by cable and bobbin, a system which had nothing to commend it except that it could be produced by a company with no gear-cutting equipment, and that it was cheap and simple. To their credit, Godfrey and Nash combined cable-and-bobbin with a proper front axle that had a steering pivot for each wheel, rather than the suicidal centre-pivoted type used on so many of the contemporary cyclecars.

1913 Grand Prix GN chassis, fitted with touring body.

1913 Grand Prix GN chassis, fitted with touring body.

1926 Frazer Nash Sports Tourer.

1926 Frazer Nash Sports Tourer.

Archie Frazer-Nash behind the wheel of one of his cars.

Archie Frazer-Nash behind the wheel of one of his cars.

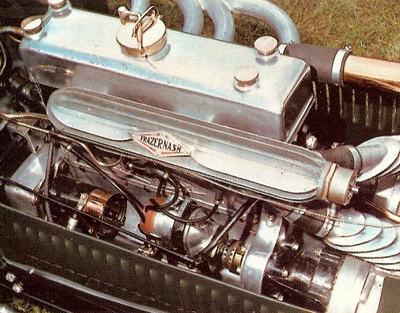

Engine from Frazer-Nash single seater.

Engine from Frazer-Nash single seater.

1936 Frazer-Nash single seat racer.

1936 Frazer-Nash single seat racer.

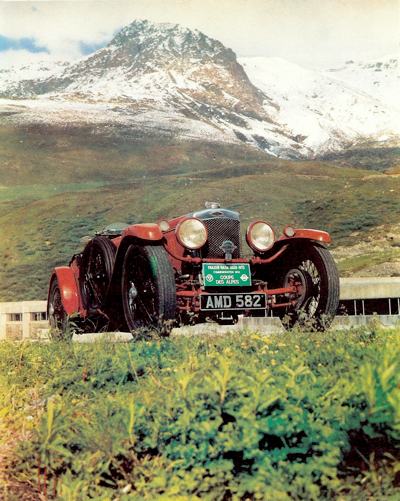

1933 Frazer-Nash TT Replica.

1933 Frazer-Nash TT Replica.

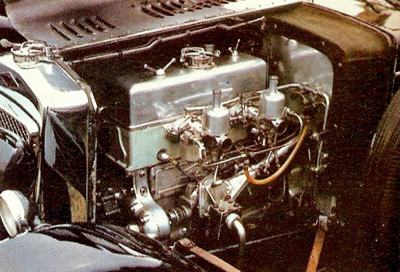

Engine from a Frazer Nash.

Engine from a Frazer Nash.

1932 Frazer-Nash Exeter model, with a 1936 TT Replica behind.

1932 Frazer-Nash Exeter model, with a 1936 TT Replica behind. |

Crude though the new GN cyclecar seemed, it met a genuine need for a light sporting vehicle that fell between the motor-cycle-and-sidecar and the small car; the GN came in as the enthusiasm for what became known as 'The New Motoring' was rising towards an unprecedented peak (the magazine The Cyclecar sold 100,000 copies of its first issue). The typical customer for a car like the GN was later summed up by popular motoring journal of the time as 'a motor cyclist of the semi-sporting type - an audacious and much-enduring type of motorist, who is usually rather reckless financially and technically much more efficient than the average car owner'.

GN owners had to endure a good deal: the JAP engines were quite unsuitable for car use, ran roughly, lacked torque and overheated. To overcome the latter defect, cooling fans were fitted but flew apart at high speed, puncturing the bullet-shaped petrol tank, mounted above the engine, thus ruining the car. Fortunately the merits of the car outweighed these minor inconveniences, and Godfrey and Frazer-Nash had to move to larger premises at Hendon 'to cope with demand; then a satisfied owner put £1000 into the business, which enabled Godfrey to go ahead with the design of a new 90° V-twin power unit to replace the JAP.

At first Peugeot cylinder barrels were used, with the automatic inlet valve converted to mechanical operation but, subsequently, GN made their own cylinders, based on the Clement engine scaled-up, with overhead inlet and side exhaust valves. The elegantly curved induction pipes fitted to these engines had originally seen the light of day as push bike handlebars! Soon, the engine was being fitted transversely across the frame for better cooling which also allowed the clutch, originally fitted on the countershaft, to be incorporated in the flywheel, with a short driveshaft taking the power to a bevel box with the two-speed chain and dog gear fitted to its countershaft. Final drive was now by belt.

Later, three-speed-and-reverse (or four-speed-forward) transmissions became available, still with belt final drive; in 1916, an employee named Sheret built an experimental model in which the belts were dispensed with and the chains drove the rear axle directly. This was the transmission adopted for post-war GNs, which also boasted a steel channel chassis and proper geared steering. Post-Armistice demand was such that GN had to look for a larger factory to replace their Hendon works, which had been adequate for pre-war production levels (the output between 1910-15 totalled around 150 cars).

British Gregoire Cars

Early in 1919, a deal was concluded with British Gregoire Cars, and GN took over their East Hill Works, at Wandsworth. Before long, a staff of 500 was employed, who, built up to 58 cars a week. A deal was also concluded with the French Salmson aero-engine company for GNs to be produced at Billancourt, near Paris, around 3000 cars being produced under this agreement. Like many other companies, GN suffered badly from the slackening of post-war demand in 1920. A receiver was called in, and the company came under new ownership. Frazer-Nash and Godfrey attempted to persuade the new management to abandon mass production and concentrate on producing sports cars for a more limited clientele, but they were over-ruled.

The 1922 models were redesigned to give more comfort, and lost their performance in the process. These emasculated GNs attracted few. customers, and so it was planned to produce a four-cylinder, water-cooled model with shaft drive, the warranty claims on which were to lead to the company's demise in 1923. Godfrey and Frazer-Nash had already resigned, the former to found a garage business, the latter to join F. N. Pickett (a colourful character who had made a fortune salvaging unused high-explosive shells from the ammunition dumps round Boulogne) in a new company called Frazer Nash Limited.

Frazer Nash Limited

The first products of the new company gave little hint of what was to follow. Frazer-Nash assembled about a dozen cars from standard GN parts, then, to counter the threat posed to cyclecars by the newly-introduced Austin Seven, fitted four-cylinder French Ruby engines in the same chassis. He also sold a few shaft-driven Frazer Nashes, which were merely re-radiatored, re-bodied Deemster light cars. A clue to the line that the firm's products were to take had been given by Frazer-Nash's sporting activities, which began in 1913 with a modest entry at Brooklands and blossomed post-war into a long string of racing, sprint and hill-climb successes, especially with the two specials Kim and Mowgli.

The Frazer Nash Rikki Tikki

These were followed by the first true Frazer Nash car, Rikki Tikki, with a Plus-Power engine. The Plus-Power was a high-performance, 1

½-liter engine produced by a company headed by Gustave Maclure, formerly designer for the British Anzani firm; this was the unit fitted in the first production Frazer Nash cars, which were built in a small factory at the bottom of Kingston Hill. Fitted with handsome aluminum sporting body-work, the new Frazer Nash offered the performance of a sports model for around a quarter of the price. The chassis, naturally enough, was based on that of the GN, but with all the shortcomings of the earlier car eradicated. It was now, for example, impossible to engage two gear ratios at once, thanks to a 'very ingenious cam-plate mechanism', and springs and axles were far more substantial.

Initially two basic models were listed, the Fast Tourer and the Super Sports, although these names referred to the state of tune rather than any other differences. From the start, Frazer Nash cars were produced to individual order, and the customer had the final say on chassis length, gear ratios, bodywork and equipment. The nearest thing then available was the

Bugatti, and that was a good deal more expensive. A major setback came only months after the company had got under way, when the undercapitalised Plus-Power company was forced to close down. Frazer-Nash had to switch power units, and chose the 11.9 hp Anzani side-valve engine, a move which involved a major redesign of the chassis. This eroded the company's cash reserves to the point of danger, and a hasty (and short-lived) amalgamation with a motor trader called W. G. Thomas, who had a larger factory across the road from the Frazer Nash works, failed to solve the problem.

The British Vulpine Engine Company

Anzani, too, were in financial trouble. They had gone into receivership in 1925, been reformed by piano-maker Charles Fox as the British Vulpine Engine Company, then, within months, were back in the receiver's hands. There was no suitable alternative power unit for the Frazer Nash. Fortunately, at the 1926 Boulogne Speed Week, Frazer-Nash met Eric Burt, of the Mowlems building company, who was persuaded to finance a new British Anzani Engineering Company which, in 1927, moved into part of the factory complex which housed Frazer Nash. These, too, were now under new management and, in March 1927, a rich schoolmaster, Richard Plunkett-Greene, invested several thousand pounds in AFN Limited (the initials stood for Archie Frazer-Nash), of which Burt's wife was also a director.

There were now four basic models: Fast Tourer, Super Sports, Boulogne and Supercharged Boulogne. Prices ranged from UK£340 to UK£585, and four-speed plus reverse transmission was available. At the end of 1928, Frazer-Nash became seriously ill, and had to give up control of the company. Plunkett-Greene took over for a while, but H. J. Aldington, who had joined GN as an apprentice in 1919, and who later became main agent for Frazer Nash cars, acquired AFN Limited and became managing director. Frazer-Nash became a consultant engineer when he came out of hospital, inventing an indicator which could be fitted to cranes to warn if they were in danger of toppling through being overloaded, and subsequently developing a gun turret which was fitted to many famous war planes, including the Wellington bombers. (Frazer-Nash died on the 10th March 1965).

While Aldington had taken over AFN Ltd, he did not acquire Anzani which, by that time, was using the same drawing office and stores facilities, as he intended to use the Meadows 4ED engine. This problem was solved by the opening of the new Frazer Nash car works at London Road, Isleworth, Middlesex, early in 1930. With the collapse of the assembled motor car industry, Anzani switched from making engines to cement mixers and pneumatic drills for Mowlems. The 'new' Frazer Nashes introduced by Aldington were a logical development of the range announced at the end of 1928, which incorporated a lowered chassis underslung at the rear, plus a rear-mounted petrol tank to reduce the fire risk.

Amalgamation with Aston Martin

Aldington strengthened the chassis frame and fitted fabric coachwork in an attempt to improve the car's appearance after a few thousand miles' hard motoring, as the old aluminum bodies had been prone to split. Twelve basic models were listed for 1930; 13 cars were sold. In 1931, came a brief amalgamation with Aston Martin, which failed to turn out the profitable venture that Aldington had anticipated, and was terminated after seven months. Aldington believed firmly in competition as a way of promoting his products but, unlike Frazer-Nash, he also believed that works cars entered in races and rallies should be identical to those available to the customer. This policy resulted in one of the most important Frazer Nash models, which was based on the team cars built for the 1931 Tourist Trophy.

The Frazer Nash TT Replica

Originally known as the Boulogne II, the car soon became the TT Replica. The Motor published a road test of the prototype in June 1931, summing it up as 'a fast and easily handled sports car with many features of unusual interest'. They added what must be one of the most classic descriptions of the Frazer Nash: 'To say that the car handles delightfully is to give a poor idea of the sheer joy that one derives from driving it. Responsive to the slightest touch, always under complete control and possessed of an acceleration which is as thrilling as it is rapid, this car is such as will satisfy the most fastidious and experienced motorist'.

The TT Replica was the mainstay of production during the 1930s, although the fabric bodywork of the Boulogne II soon gave way to steel panelling, as it proved even less durable than aluminum. Altogether, around 90 TT Replicas (including the almost identical Byfleet model and the rare supercharged Shelsley variant) were built between 1932 and 1938. A new, smoother power unit, the six-cylinder Blackburne engine, appeared in 1933, followed a year later by the single-overhead-camshaft 1

½-liter Frazer Nash engine assembled at the Isleworth factory to the design of Albert Gough from parts specially built by Beans Industries at Tipton.

At last, AFN were making money and, in June 1934, they acquired the moribund Anzani company to assemble the Gough engine (here, too, was built the twin-cam Anzani engine fitted to the Squire car). A boost to sales was the works team's performance in the Alpine Trials of 1932, 1933 and 1934, in which Frazer Nash cars won four Glacier Cups for completing the difficult course without loss of marks. At the other end of the scale in 1936, the company catalogued a single-seater racing car, with a 135 mph top speed, obviously inspired by the success of the ERA. Price was only UK£1050, but production did not go ahead. However, the car did take the 1500cc record for the Mountain circuit at Brooklands at an average speed of78.73 mph, and lapped

Brooklands at 120 mph driven by Miss Margaret Allen.

The car's power unit was a modified Gough with a supercharger. The 1936 catalogue listed a wide range of cars - the Falcon, the Colmore, the TT Replica, the Ulster 100, the Supercharged Shelsley and the Single-seater. After World War 2, Aldington persuaded the Bristol Aviation Company to take over production of the BMW 328 engine, which formed the basis of a new Frazer Nash car, which had a tubular chassis, transverse-leaf independent front suspension and torsion-bar rear suspension, plus sliding gear transmission. A Frazer Nash High Speed model came third in the 1949 Le Mans 24 Hours, driven by Aldington and Normah Culpan, so this new Frazer Nash became known as the Le Mans Replica.

A similar car, driven by Franco Cortese, won the 1951

Targa Florio, the first ever British victory in this event;

Stirling Moss took first place in the British Empire Trophy in the Isle of Man the same year, with another Frazer Nash second. A works racer, the lightweight Le Mans Mk II Replica, appeared in 1952, driven by Ken Wharton, but this glassfibre-bodied special was not a success. De Dion axles were available on some models from 1953_on, and a V8 BMW power unit subsequently became available in Competition and Continental Coupe models, only to be discontinued after 1957. It was the old BMW unit, uprated to 3.2 liters, which powered the last Frazer Nash cars; these faded from the scene in 1960. Thereafter, the company concentrated on their Porsche agency.

Also see: Lost Marques - Frazer Nash (AUS Edition)