|

ZIS and ZIL

|

1918 |

Country: |

|

|

Sons and Daughters of the Revolution

It is a subject of conjecture as to when the Russian auto industry actually began. Popular opinion seems to have it as the 28th June 1918, when Lenin visited the AMO engineering works in Moscow and made a stirring speech, promising the sons and daughters of the Revolution that Russia would now step into the motor age.

It took a while - the country was still in a considerable state of turmoil in the wake of the war and the revolution - but in 1924 the first products from the AMO Works, AMO F 15 trucks, rolled across Red Square as part of the 7 November revolution anniversary festivities, and this is regarded as the semi-official date of birth of the motor industry in Russia.

Autotrust

In 1925 a new State department, Autotrust, was formed for the purpose of planning and building the motor industry, and under its auspices production was increased. While the trucks - based on a Fiat design but built entirely from domestic-produced materials - were proving themselves up to the tough conditions, and even won a 2000 kilometre rally without a single break-down, a series of cars based on the truck chassis and engine was built at another works at Yaroslav.

Zavod Imiemi Stalina

Between 1925 and 1931 around 300 of these cars were produced. Meanwhile the AMO works, which was really only a collection of sheds, were rebuilt between 1928 and 1931 with the capacity to produce 25,000 trucks a year on proper production lines, and the new factory was renamed ZIS - Zavod Imiemi Stalina - in honour of Josef Stalin.

The Great Patriotic War of 1941-1945

Up to the beginning of World War 2 - in Russia known as the Great Patriotic War of 1941-1945 - the ZIS works turned out its quota of trucks successfully, and here and elsewhere Russia produced 25,000 cars annually, including large numbers of compact front-wheel-drive military vehicles. At ZIS the country's luxury limousine was produced from the mid 1930s.

Called the Model 101, it was generally similar to large American cars of the same period. The 5.5 liter engine was almost identical to the

Buick straight-eight. Transmission was three-speed with synchromesh, and the car had semi-elliptic springs front and rear. These cars were produced at a rate of only two a day to special order by government departments, and were used only by officials and professional men in high office.

The Chiefs move to the Urals and the Volga

On the eve of the war the ZIS works were producing twenty models of motor vehicles, including buses and three-ton trucks, particularly as export orders had been received. During the war the factory equipment and top staff were moved for safety to the Urals and the Volga, where the Cheliabinsk, Miass and Ulyanovsk car and truck works and the Irbit motor-cycle works were established. Post-war, the. ZIS works re-opened to produce mainly medium trucks, with bus production moved to Likino. Autotrust was reformed as Sojuzglavavto-Zagranpostavka, or Ministry of the Automobile Industry, and set a target of 75,000 Russian cars a year, which was achieved in 1950.

A worker on the ZIS production line, at the Lykhachev machine shop.

A worker on the ZIS production line, at the Lykhachev machine shop.

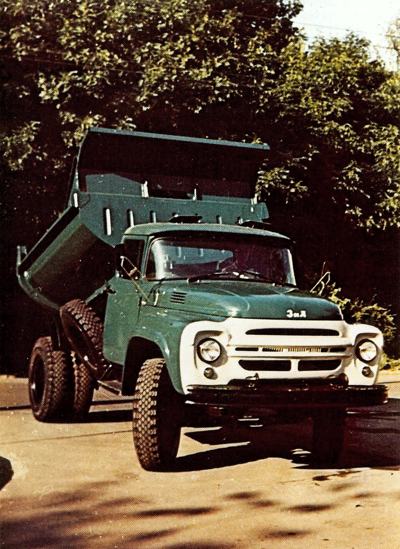

ZIL MMZ 555B.

ZIL MMZ 555B.

The mixed production line at the ZIL plant. The car in the foreground is a 111G 6 liter 230bhp V8 circa 1965, reputed to have had a top speed of 106 mph.

The mixed production line at the ZIL plant. The car in the foreground is a 111G 6 liter 230bhp V8 circa 1965, reputed to have had a top speed of 106 mph.

ZIL 131 Dump Truck.

ZIL 131 Dump Truck. |

ZIS Model 110 / Packard Series 180

The ZIS works contribution from the end of 1945 was the Model 110. This had been planned as early as 1942, and was close in design to the Packard Series 180. A Russian trade delegation had gone to Detroit and purchased Packard dies, and these were skilfully adapted to cut down lead time for the new ZIS. The Model 110 had an 8-cylinder 137 bhp side-valve engine with three-speed synchromesh gearbox, and gave up to 90 mph - though fuel consumption was no more than 10 mpg. Standard equipment included electrically operated windows and folding occasional seats. So once again, to the Russians, ZIS was synonymous with automobile luxury-and high officialdom.

Some tourers and a number of ambulances were also built on the 110 chassis. In the mid 1950s prototype work was done on a seven-seater Moskva limousine with 8-cylinder engine, but this project was abandoned in favour of the ZIS III, which appeared in 1956. Like its predecessor it owed 'much to Packard including the frontal styling. An III-V tourer version was built, and a 112 sports version with four-seater open bodywork put the Soviet speed record up to 300 kph. The same car achieved 245 kph on a banked circuit at Dmitrov, near Moscow, during the 1970's. The engine was a V8 of 220 bhp driving through an automatic transmission with push-button shift. Power brakes and power-assisted steering were among the pleasant features which the Soviet motor industry allowed the country's top brass.

Ivan A. Likhachev, and ZIS becomes ZIL

At this time, Stalin's name fell into disgrace, and the ZIS name became officially an embarrassment. But in the worldwide tradition of car makers, for whom a change of name has always provided a convenient way out, the factory was renamed Zavod Iniemi Likhachev, after Ivan A. Likhachev, a former director of the plant and a pioneer of Russian car construction. The cars were given a new badge, ZIL, and the old ZIS models simply became ZIL's from 1956 onwards.

A prototype ZIL with six headlights and a mixture of Ford and General Motors styling ideas appeared in 1960-though the Soviet Union was involved in the 'cold war' with the United States, its car stylists were in no way inhibited from copying US car design. Though this model was never produced because it was apparently thought too flamboyant for the usually grim-faced and soberly-dressed Soviet officialdom, the greatly-revised III of 1963, the III-G, was very General Motors in appearance. This car had a six-liter V8 engine producing 230 bhp at 4200 rpm, and a reported top speed of 106 mph - 'reported' because fine detail was not being released to the West on most Soviet vehicles of this type.

The ZIL 114

In 1970 a new seven-seater ZIL limousine was announced-the 114 with a 7-liter V8 engine and razor-edged styling above the waistline, yet again showing American influence. And yet again top Soviet officials were treated to the best features that the automotive world had produced, including air conditioning. It was during this time that, in the west, ZIL were best known as the producer of official limousines, but to the Soviet people it was one of Russia's top industrial organisations and a formidable truck producer. ZIL had nine factories around the Soviet Union, and was served by more than 700 other component firms.

After 1970 the main Moscow works - on the site of the original AMO plant - were vastly expanded and modernised, the addition of 300 new automated and fully mechanised assembly lines bringing ZIL's total lines to some 800, adding up in distance to more than 100 km. ZIL technologists became among the most skilled in the world, with advances including the production of new high-strength steels and advanced heat-treatments to increase the reliability and durability, particularly of their heavy-duty truck components. ZIL were especially proud of their castings, with foundry mixes based on synthetic resins, duplex furnaces, and the monitoring of metal composition by X-ray. This resulted in a claimed forging rejection figure of only 0.62 per cent.

A Model of Soviet Motor Industry Paternalism

Computerised production control was then introduced, and small computers controlled machine tools and units on the automatic production lines. Wheel drum hubs, cylinder liners and pistons were machined automatically, rear axle housings automatically welded, and the continuous overheads parts delivery systems are comparable to those elsewhere in the car world. During this time the ZIL organisation remained a model of Soviet motor industry paternalism. In addition to a technical centre which taught its workers their factory skills, ZIL also ran four general education secondary schools and three technical colleges, one of them a university-level college.

The ZIL Palace of Culture

ZIL employees lived in company-owned flats, with amenities somewhat beyond those available to the average worker. The ZIL factory had a Palace of Culture with winter garden, concert halls and theatre, and its dance and opera sections have produced some top Soviet and international arts festival winners. Some 8000 Muscovite children attend ZIL's hobby groups. In all, ZIL was a 'total package' of work and play not dissimilar to that practised by Japanese motor firms at the time.

The ZIL-130 Truck

What is probably less well known is that, during the 1970s, ZIL vehicles could be found in 57 countries - more than 300,000 were exported by the Soviet motor industry export agency Avtoexport, and some 5000 mechanics were trained in various foreign markets. Adaptability was the keynote of ZIL truck design - the ZIL-130 truck was the basis for sixty different versions, and the group which devised it won a USSR State Prize. Powered by a V8 engine giving 170 bhp, it has a three-seater cab, hydro-assisted steering, rather long springs front and rear with telescopic dampers, and could carry six-ton loads over rough roads at a steady speed. A modified 130-G version with 700 mm longer wheelbase could take long or low-gravity loads.

The ZIL MMZ-555 was a dump truck for construction sites and quarries, and handled bulk and semi-liquid loads quickly on difficult sites, being notably manoeuvrable. The ZIL 131 and 131A models had three-axle, six-wheel drive and are designed for cross-country work in particularly difficult conditions. These trucks could negotiate water three-feet deep, and mechanical refinements which aided the driver included an automatically engaging front drive and a device which enabled them to change the air pressure in the tyres while on the move to suit the conditions.

LAZ and LIAZ buses and in Ural-375 Trucks

ZIL engines were used in LAZ and LIAZ buses and in Ural-375 trucks, and the firm participated in the Kama River truck project which formed what was for a time the world's largest truck-manufacturing complex with a capacity of 150,OOO diesel trucks and 250,000 diesel engines a year. ZIL designed the basic production facilities and also produced the prototypes of the KAMAZ trucks.

Also see: The History of ZIS and ZIL - Cars for the KGB (AUS Edition)